Aleut Federal closed out FY24 on a high note! To maintain that momentum into the next year, AF brought together senior members of their management teams to Reston, Virginia, to collaborate on department goals, as well as align on the company’s strategic vision for the upcoming year.

Several members of the Aleut Board were able to attend, chat with AF employees, and have dedicated time with leaders of each line of business.

Aleut Federal has a dispersed workforce operating in numerous locations throughout the country. Having the opportunity to come together, build a stronger connection to our region and shareholders, and be able to meet with our Board primes Aleut Federal for continued growth and success.

President & CEO, Skoey Vergen, and VP of Regional Affairs, Julie Toomey, were honored to present on the importance of Aleut’s mission, highlighting how Aleut Federal’s work directly impacts our shareholders.

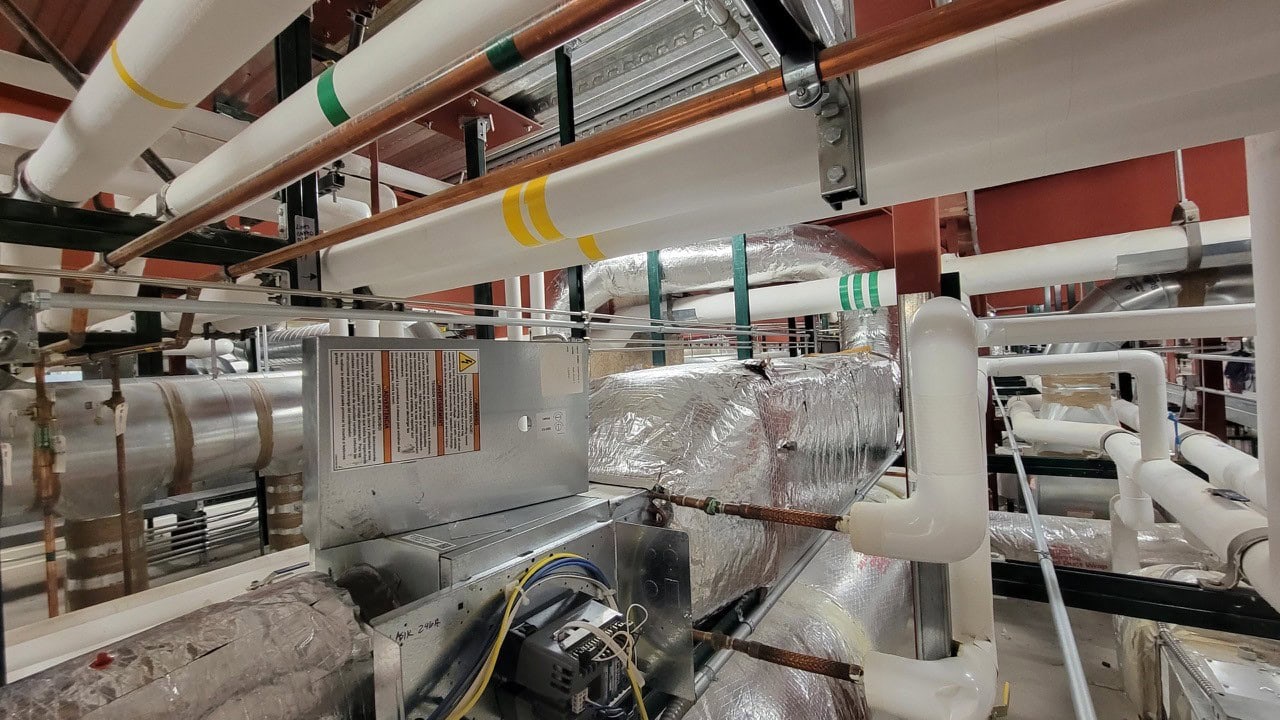

Aleut Patrick Mechanical (APMH)

Aleut Patrick Mechanical is headquartered in Fairbanks, Alaska and primarily installs complex mechanical or utility systems for commercial customers in the Fairbanks North Star Borough. APMH’s focus has been expanding their customer base beyond Fairbanks and recently has been working on renovation projects for the barracks on Joint Base Elmendorf Richardson in Anchorage, AK. Fort Wainwright army base, Holland America along with University of Alaska Fairbanks, and Fairbanks Memorial Hospital, are some of APMH’s largest customers in the Fairbanks area.

Aleut Real Estate (ARE)

ARE is in a rebuilding phase after selling underperforming real estate investments over the last few years and is now evaluating potential opportunities in Anchorage and outside Alaska for future investments. Through the process of rebuilding, the team is developing a pipeline of opportunities. ARE is continuing Aleut Plaza improvements throughout 2024. Stay tuned for more updates soon.

Aleut Enterprise (AE)

Frosty Fuels, an Aleut Enterprise subsidiary that provides fuel to the city of Cold Bay, added a new deicing truck to their rotation. By expanding their service offerings, Frosty Fuels can attract potential new business for Frosty Fuels and Cold Bay. The de-icer will be ready for service this winter.

This year, Aleut Enterprise is also working to secure additional fuels trucks in the Cold Bay and Adak communities as back-up in case of mechanical issues. These are large investments, but critical to the individual communities. More updates to come regarding the additional fuel trucks.

Strata-G Solutions (Strata-G)

Strata-G Solutions, based in Huntsville, Alabama, specializes in manufacturing and design engineering, operating out of a spacious 40,000 sq ft warehouse. Through Strata-G’s tireless work ethic, commitment to growth, and dedication to our shareholders, they had a successful fiscal year (April 1, 2023 – March 31, 2024). This allowed Strata-G to upgrade and expand their machining capability by purchasing the Mazak i800T.

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting.

Most of the machining in Strata-G’s industry is accomplished through computer numerical controlled (CNC) mills and lathes, traditionally two separate (and large) machines. The Mazak i800T performs both mill and lathe operations all in one machine, utilizing multi axis approaches. This reduces the number of overall “set ups” needed to process the part. Less “set ups” means a more efficient process and higher accuracy, resulting in less waste.

And its footprint is not as big as you’d expect. It’s about as tall and wide as a school bus, but only half as long. However, it weighs 44,000 pounds, about the equivalent of seven midsize cars.

The Variaxis i-800T is scheduled to be delivered in May 2024.

Not only does the machine add capability, accuracy, and efficiency; it provides a growth opportunity for our team members by allowing them to work with one of the more sophisticated machine tools offered.

To get started in this type of work, most machinists have an associate degree or a certificate in Machine Tool Technology. CNC programmers typically have years of CNC and multi axis experience, plus additional training on specific CAD/CAM programs.